During a major stormwater and drainage program, Brisbane City Council discovered that a culvert running under the busy Brisbane Corso was reaching the end of its structural lifespan. The 13-metre inverted-arch culvert needed to be rehabilitated with a structural lining within 6 months to continue its safe operation.

At first, a cast in-situ concrete lining seemed the obvious choice for rehabilitating a culvert of this size and condition, but after careful consideration, the tidal constraints posed by the Brisbane River and the construction footprint required to overcome them ruled this option out. Brisbane City Council now needed an innovative new solution to the problem posed by their deteriorating asset.

Working closely with Council, Interflow proposed the use of Channeline, a fully customisable and modular lining solution that could be installed quickly, safely, and with minimal community impact. This innovative product allowed crew members to deliver project works around tidal movements, which avoided the need to build a costly and invasive cofferdam.

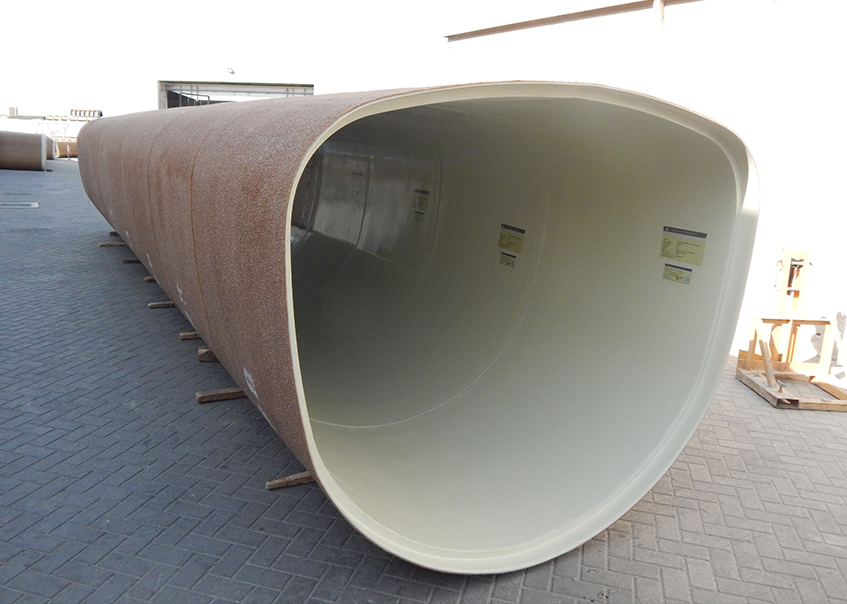

The prefabricated 1.2-metre units were winched in place and positioned using pre-installed timber and steel rails. The segments were then sealed, and the void around them filled with grout.

By implementing this innovative Channeline solution, Interflow was able to restore Council’s asset with minimal impact on the community and environment. This renewal project was so successful that Brisbane City Council is now considering this solution for other deteriorated, non-circular pipes and culverts throughout the region.

Brisbane City Council identified an aging box culvert in need of structural rehabilitation.

Opening to the Brisbane River, the culvert was exposed to the rising tides. Traditional concrete rehabilitation would require the construction of a cofferdam to keep the culvert clear of river water while concrete was placed and cured – a costly exercise with a large construction and environmental footprint. Adding to the constraints, it was crucial that works have as little impact on the local community as possible, ruling out any solution that relied on road closures or traffic diversions.

An innovative solution was needed to extend the life of this aging city asset while minimising the impact on the lives of the commuters and locals above.

The local team searched far and wide for the best solution to Brisbane City Council’s problem. The answer was Channeline, a fully customisable and modular system that could be installed quickly during low tides.

The segments were engineered to match the unique geometry of the culvert and be strong enough to take the load without relying on the existing concrete structure. Fabricated in 1.2-metre lengths for easy handling, the pipe segments were then winched in place and sealed to form a complete, structurally-sound tunnel.

Channeline allowed renewal works to go ahead without the need for invasive preparations and disruption to the community.

Interflow answered Brisbane City Council’s call for an innovative way to renew a failing box culvert located under a busy urban street.

Thinking beyond the traditional concrete relining approach, Interflow proposed the use of Channeline, a bespoke, modular lining system that could be placed without expensive cofferdams or extensive road closures.

By listening to our customer’s needs, Interflow found a solution that minimised cost and community impact while securing the future of an aging asset.